Engineering Consulting & Simulation Services

Delivering advanced finite element analysis, expert material modeling, and data-driven solutions to optimize engineering performance.

Services

What We Offer

We offer advanced engineering simulations, precise material modeling, and data-driven analytics to optimize your designs, enhance durability, and accelerate product innovation.

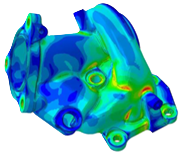

FE Simulations

We deliver advanced Finite Element Analysis (FEA) to accurately predict structural integrity, durability, thermal behavior, and mechanical performance. Our simulations empower you to confidently optimize designs, reduce product failures, and improve overall performance and safety.

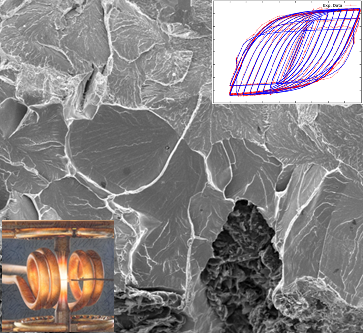

Material Expertise

With deep expertise in materials science, we specialize in fatigue modeling, thermo-mechanical fatigue (TMF), and advanced constitutive modeling, transforming material testing data into reliable, simulation-ready material models. By seamlessly integrating Integrated Computational Materials Engineering (ICME) processes into your product development workflow, we bridge the gap between materials science and practical engineering applications—enhancing durability predictions, improving reliability, and accelerating innovation and product performance optimization.

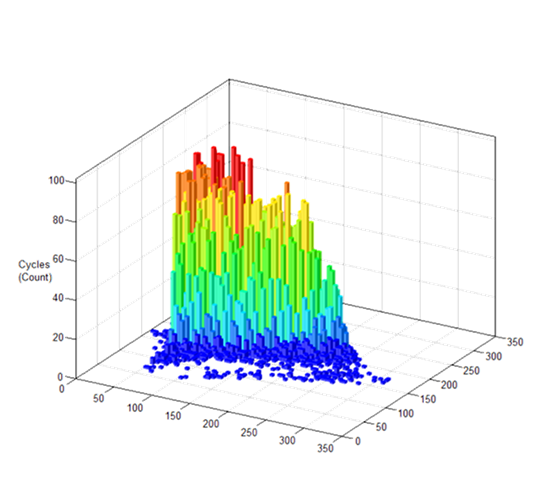

Data Analytics

Leveraging powerful data analytics and AI-driven automation, we streamline complex engineering simulations, turning data into actionable insights. Our solutions reduce uncertainty, accelerate decision-making, and enable smarter, more efficient engineering workflows.

Custom Engineering Solutions Designed for You

At TruNumerics, we understand that no two engineering projects are identical. Our team collaborates closely with you to understand your specific requirements, objectives, and technical challenges. We then tailor our simulation, fatigue analysis, and material modeling services to precisely match your unique needs. By integrating advanced analytical methods, validated data-driven models, and customized simulation workflows, we help you enhance design accuracy, optimize performance, and reduce risk. Whether you’re tackling complex product design, solving durability issues, or pioneering new materials, our customized solutions deliver measurable outcomes and confidence at every step.

Expertise That Powers Results

At TruNumerics, our team brings extensive experience in advanced simulations, structural integrity assessments, high cycle fatigue and thermomechanical fatigue (TMF) modeling, and materials science. With a proven track record of success in industries ranging from automotive and aerospace to energy and heavy machinery, our specialists combine deep technical knowledge with practical industry insights. Leveraging sophisticated FEA methods, predictive material behavior models, and state-of-the-art AI-powered workflows, we consistently deliver solutions that improve product durability, reduce failures, and maximize operational efficiency. Partner with us to translate engineering expertise into real-world advantages, achieving safer, stronger, and more cost-effective products.

Our Work

Client Cases

Explore real-world examples showcasing how TruNumerics has successfully solved engineering challenges through advanced simulation, innovative material modeling, and data-driven insights.

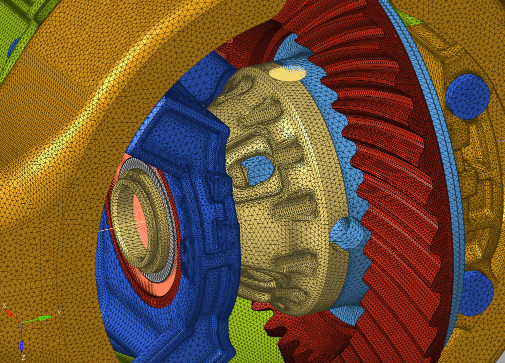

Driveline System FEA Project

Performed comprehensive Finite Element Analysis (FEA) on automotive driveline systems, accurately predicting structural behavior under dynamic loading. The analysis resulted in optimized component designs, significantly reducing weight, improving durability, and enhancing overall system efficiency.

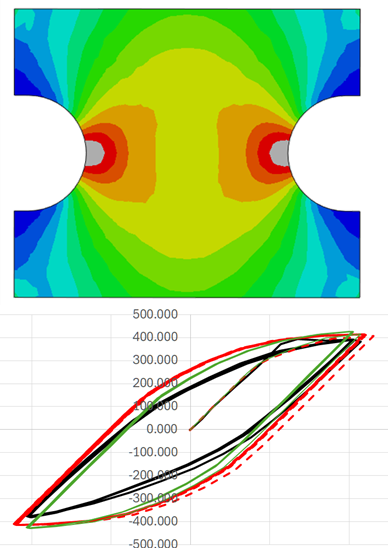

TMF & Viscoplasticity Model Development

Developed advanced Thermo-Mechanical Fatigue (TMF) and viscoplasticity material models to accurately simulate material behavior under complex thermal and mechanical loading conditions. This enabled precise fatigue-life predictions, ensuring product reliability and reducing validation costs.

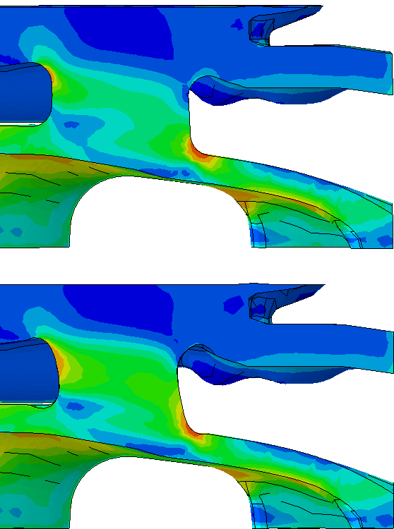

Cylinder head water-jacket shape optimization

Conducted structural optimization of engine cylinder head water jackets using simulation-driven methods (Abaqus + Tosca Structure). This approach led to a significantly optimized geometry, improved cooling efficiency, and substantial reductions in design iterations and development time.

Partner with TruNumerics Today

Ready to Accelerate Your Engineering Project?

Discover how TruNumerics’ advanced simulations and material expertise can help solve your toughest engineering challenges.